en

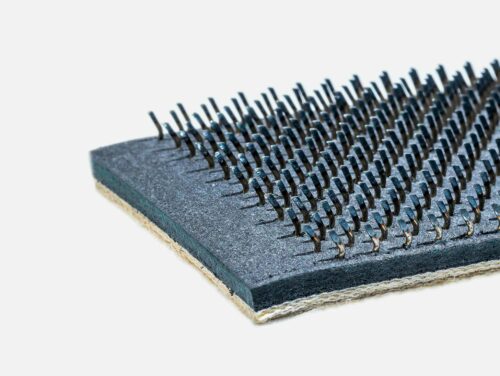

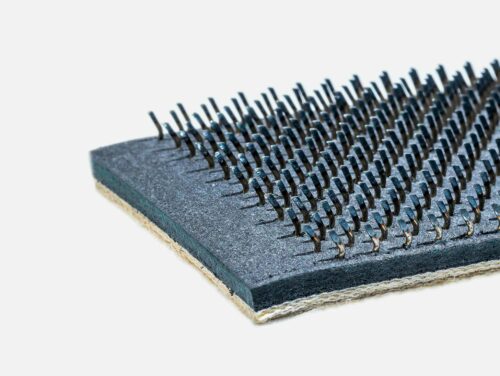

For many different applications in wollen, non-woven and worsted spinning we manufacture approved card clothings with the following technical specifications.

Wollen Spinning

WORSTED SPINNING

For many different applications in wollen, non-woven and worsted spinning we manufacture approved card clothings with the following technical specifications.